Sabre Blog

Boat building really is a big puzzle and only the designers and production people really know how everything is going to fit together. They have lived with it for about 18 months now, day and night. Once the assembly is done for the first time, the processes are written and the ongoing assembly of future hulls of the same design eventually works into a routine. I guess that's a good way to describe custom boatbuilding versus the semi-custom work that we do at Sabre. We do it over and again while custom builders do it just once and every boat is, for them, like our prototypes. Thanks to CAD technology first-offs and custom boats are not as hard as they once were but they still are very complex. Over the next ten weeks I 'll follow the process with you as the first Sabre 40 goes through it's metamorphosis from liquid resin in a barrel, boards and sheets of wood, coils of wire and hundreds of purchased parts, to become a beautiful living thing: A fine yacht.

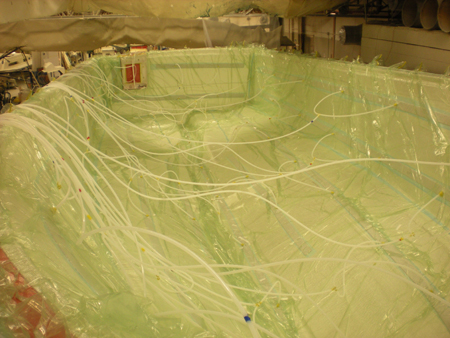

Last week the glass shop infused the first deck. Decks are built upside down so that gravity is our friend and not our foe. Here you see that the two tone gelcoat has been sprayed on the mold and the stack of fiberglass and core have been laid in and stitchedd together. The tubes that will feed resin into the stack are in place. This image was taken about ten days ago. The resin infusion process took about 1.5 hours to do and the part sat overnight. It was then released and flipped into it's upright mode. I'll show you more of what's going on with the deck next week

Posted in Sabre Yachts Blog | Comments Off on Fitting all the pieces together

With the hull of our first boat on the line, everyone from the hull team to mechanics and electricians are busy doing their part to make the Sabre 40 come to life. Our two top mechanics seen here took very little time to install the two Zeus pods in the hull. Tony Lorraine, the fellow working on the starboard pod, has done many Zeus installations on the Sabre 42 Express and so has the knowledge to impart to Les Morray who is working on the port pod in the picture.

First operation was to cut the fiberglass to create the opening for the pod. Wow, the glass is thick in that area! In total about 1.25 inches of solid glass. Then a template is used to drill the holes for the fasteners around the clamp rings and the rubber gasket that seal the hull and keep sea-water where it belongs. Soon the engines will be placed in the hull forward of the engine room bulkhead and drive shafts will couple to engines to the pods. But that's for another day

Posted in Sabre Yachts Blog | Comments Off on Zeus Pod installation is done

European builders have been including their swim platforms in their LOA dimension for decades. When the EEC and our own US boat building standards groups got together to talk about it, the decision was made that a builder could include their platform in the LOA of it is molded as part of the hull mold. For a number of practical reasons our platform is made as a separate part and then mechanically attached to the hull. So we're actually a 43 foot long 40 footer if you are comparing the new Sabre 40 to other boats in her class.

What you see here is the plug of the swim platform: the model that is created in order to create the mold. We listened to a lot of your comments about dinghy storage and you told us that you want to have your "annexe" (as the French call it. I always loved that description, it seems so appropriate), along on your voyages. We made this platform extra deep at 35". In addition, with the transom of the yacht being forward sloping, the dinghy can stow further forward on the platform. We do not currently have any specific suggestions as to makes and models of dinghy storage systems but having this large platform to work from will make our owner's choices far more appealing.

Posted in Sabre Yachts Blog | Comments Off on How long is your 40 footer?

Two tone non-skid is a topic that puts a lot of people to sleep so I'll make it short. Gelcoated boat decks get their exterior color before anything else happens in the deck mold. Gelcoat (the paint color you see) is sprayed into the bare mold. Here the mold surfaces are black.

All Sabre models have both smooth and diamond patterned non-skid in the mold surfaces. In order to create the two tone effect a number of steps need to be taken. Step one is to tape off (as you see here) and cover with plastic, all of the shiney surfaces (i.e. the surfaces without non-skid patterns). Then the gelcoat color for the non-skid is sprayed into the mold. Once that has set up we remove the tape and plastic exposing the shiney surfaces and spray the base color onto the mold. When released, the deck will have the two tone look.

And now you know.

Posted in Sabre Yachts Blog | Comments Off on How do they do that ?

While the wood, mechanical, electrical and other departments ready themselves for the first Sabre 40 Sedan to go on line, the associates in the glass shop proudly released the first hull from the mold on Tuesday. She has spectacular lines. Tough to get a good photo of her so far due to all of the gear surrounding her but take my word for it, she is very elegant !

More later today. Things are happening now.

Posted in Sabre Yachts Blog | Comments Off on A Star is Born

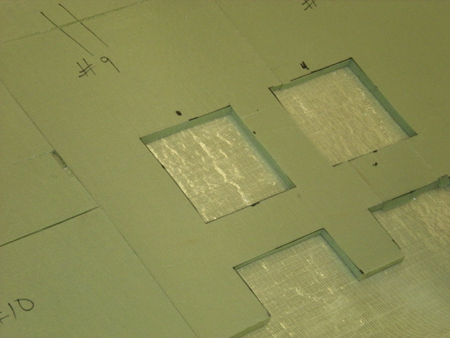

I am often asked how we treat through hulls with hull coring. You see, the old, less than stellar reputation that balsa cored hulls had was often the result of the way less conscientious builders managed through hulls. We have always removed core in zones where through hulls are going to penetrate the laminate but like all things quality it takes a little more time and effort. Here's an example of the Sabre 40 hull laminate where Airex PVC foam core has been removed to provide a solid glass zone for installation of raw water intakes.

This image was taken prior to the fiberglass stack being added to the inside of the Airex PVC foam core. Foam cored hulls provide the best structural ccharacteristics while lowering overall part weight. For the consumer that means lower fuel costs.

Posted in Sabre Yachts Blog | Comments Off on Cut it out !

Not for the boatbuilders doing it.

The first hull part for the Sabre 40 was infused this week and what once took almost one week of labor with traditional hand laid techniques was accomplished in just a few hours; Granted the prep time is much longer but overall hours have been saved, less resin has been used and a better part has been produced.

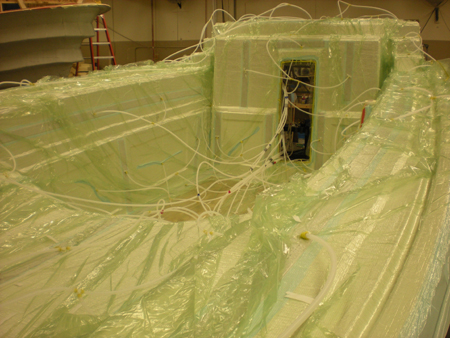

But I need to explain what you're seeing here. The mold has been sprayed with the exterior color (gelcoat) of the hull. Then, all of the fiberglass and coring materials (a.k.a. the laminate stack) have been laid dry in the hull. Once all of the structural materials are in place, a very large plastic bag is laid over the top of the entire part. Hoses are run through the mold at strategic places. Some of the hoses will introduce resin into the bag and others will draw air out of the bag. A seal is made around the edge of the entire bag. The pumps are then turned on pulling catalyzed resin into the part and infusing that resin into the laminate stack. Once all of the materials are wetted out the pumps are stopped and the part is complete.

The next day, our boatbuilders are back in the hull part preparing the engine beds and stringers

Posted in Sabre Yachts Blog | Comments Off on Infusion Confusion ?

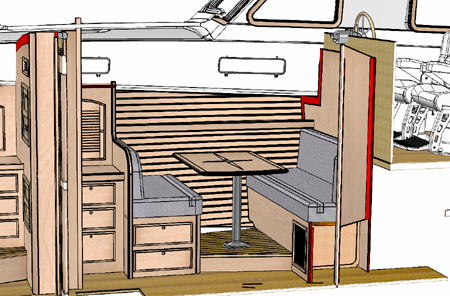

Many potential clients for the 40 Sedan have asked about alternative layouts for the 2nd cabin. Some year's ago I was aboard a Jersey 40 that belonged to some good friends of ours from Cape Elizabeth, Maine. We spent one amazing evening on board their boat and the functionality of their boat's interior layout stuck with me to this day. The Jersey 40 was built with a mid galley and a second cabin which they had set up as dinette. As dinner preparations took place, the chef was still very much a part of the social gathering in the salon and once the dinner bell was rung, we moved down to the dinette for an amazing meal.

When the 40 Design Team was faced with presenting another layout for the 2nd cabin the dinette idea came forward and I could not have been more excited. This is a layout that works. You see I am blessed with four grandchildren and have a fifth on the way. When kids are on board they want their own space and the 2nd cabin solves that nicely. In the dinette version they can sit up and draw, read or play games at the table. A cruising boater might use this set-up as an office and the table is a perfect space for a lap top. Come bed time and the table can go down and make a nice berth for the grandchildren, a guest couple or maybe even for a snoring spouse.

I am a fan of the dinette ! Are you? Tell us what you think.

Posted in Sabre Yachts Blog | Comments Off on Sabre 40 Dinette layout

The other day I heard a comment from a competitor that Sabre had not specifically designed the 42 Hull for Zeus. That is an incorrect statement. I only hope my competitors read my blog so they too will learn from it. When we decided to use the Zeus pods on the 42 Express we approached Cummins and they agreed to use their own naval architect Cotty Fay to determine the suitability of our existing hull for this application. After a full review Cotty worked with us on the tooling of the Zeus mold inserts and agreed that we had a perfect design for their product. Our sea trials have proven that he (and we) were right. Check out the video .

Here is an image of the insert that creates the flat in the hull for the Zeus Pod. It's bound to promote some conversation so I'll just drop it there and wait for questions.

The Sabre 40 hull and inserts were developed in concert with Cummins and Cotty Fay. Rest assured clients (and competitors) that this one will run just as beautifully as the 42 Express and that is a very sweet ride.

Posted in Sabre Yachts Blog | Comments Off on Hull Design and Zeus

After months of design work and tooling construction, the hull mold of the exciting new Sabre 40 arrived in Maine last week. Now the boat will truly start to take shape.

The evolution of the Sabre design team's work comes to life with the style of this new yacht. Following on the success of the Sabre 52, the Sabre 40 transom is softly curved and slopes aft, creating a very elegant line. And our engineering team has developed a method of installing a curved transom door (not an easy task) in this shape, so that she looks great underway as well. These refinements in style are what has led to the success of each addition to the range over the last ten years since we first launched the benchmark Sabre 42.

Seemingly insignificant in the big scheme of things, these styling cues really do make a difference to the lovers of great boats.

Posted in Sabre Yachts Blog | Comments Off on Sabre 40 hull mold arrives, boatbuilding begins